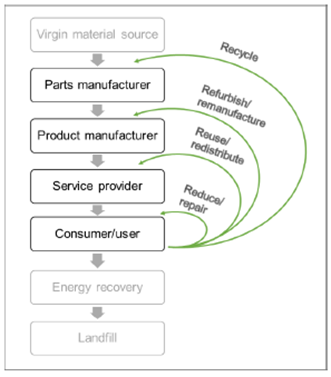

In short, Circular Economy (CE) is about creating closed loop material flows keeping products, components and materials at their highest utility and value and use them through multiple lifecycles. It is also about waste prevention, resource efficiency, leakage minimisation and dematerialisation: Raw materials are added for manufacturing and re-manufacturing of products or components already in the system. These have been recycled or re-used by the consumer maybe several times already. Waste is almost non-existent but only leaves the system as residual waste if no further use is possible. CE opens the doors for innovative actors, it can create new businesses and markets, create jobs and make room for creative product innovations fit for closed loop material flows. The figure below shows the possibilities for closed-loops in a classic value chain.

Figure 1: Simplified circular economy model [1]

The models idea of a closed loop product lifecycle can be seen clearly. The loops can be closed along the different stages of the product lifecycle which are based on the 4R principle of repair/reduce, reuse, refurbish and recycle. Thereby it can be said that the smaller the loop, the higher the material and energy efficiency. For example, repairing a product such as a bike has a lower need for raw materials and energy than a redistribution with potentially long transportation or than refurbishment where old parts could be entirely replaced by new parts from raw materials.

Product design can largely influence a products durability, repairability or remanufacturing. This can support recyclers to “disassemble products in order to recover valuable materials and components”[2]. The manufacturer needs to be willing and able to recirculate their product. An important enabler is a durable product design which can go through several consumption circles. Such a design and also the product take-back should be incentivized for the manufacturers. Acting as an economic tool on the producers side is the Extended Producers Responsibility (EPR) which can be seen as a modern version of the polluter pay principle. However, there is a shared consumer and producer responsibility as without understanding, acceptance and demand on the consumer’s side businesses need to work ever so much harder to change their products.

Nonetheless, the demand for clear concepts on how to approach the challenges of climate change, environmentally friendly product design and low-emission products increases. CDP as a non-profit organisation is the world’s largest investor initiative. It is a rating platform for emission data and climate strategies from companies, suppliers and cities, but also the responsible use of water, the protection of primary forests and the management of environmental risks in the supply chain. In 2020 more than 9.600 companies disclosed with CDP – 14% more than in 2019, and 70% more than when the Paris Agreement was signed [3]. This is a clear sign for the interest of customers, investors and businesses in sustainable, climate conscious companies.

The DFGE can support you in many ways. With regard to product design the DFGE can support you in evaluating the environmental impact of a product. Additionally, the DFGE can support you in estimating comparative emissions: what is the emission impact of your conventional product in comparison to a redesigned product. As a long standing CDP Partner the DFGE can of course also support you if you wish to join the companies disclosing with CDP, check your gaps and improve your rating. If you need support, visit DFGE’s website, contact us at or download the DFGE Circular Economy Whitepaper.

[1] adapted from Ellen MacArthur Foundation (2013): Towards the circular economy – Opportunities for the consumer goods sector. Ellen MacArthur Foundation

[2] European Commission 2015: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52015DC0614

[3] CDP 2020: https://www.cdp.net/en/companies/companies-scores